Thermography

- Home

- Thermography

Partner With Us for Safety Excellence

Have questions? Get in touch with us anytime, or connect with us by phone for faster support.

- +91-7015864416

- sales@drsafetytraining.com

- SCO 215 ,Sector 37-C Chandigarh-160036 ,UT (India)

Thermography – Spotting Problems Before They Get Worse with Dr.SAFETY

Ever wished you could see problems before they actually blow up and cause damage? Well, that’s exactly what thermography helps you do—and that’s where Dr.SAFETY comes in. We believe in solving issues before they become emergencies, saving time, money, and hassle. It’s like having X-ray vision, but for equipment, wiring, and systems that are hidden under panels or buried in walls!

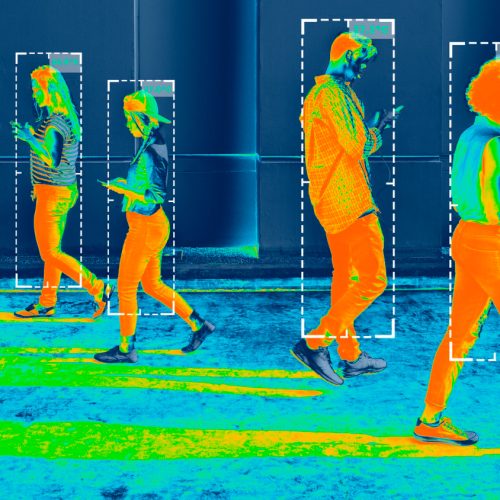

What Is Thermography (Without All the Jargon)

In simple terms, thermography is a way to “see” heat patterns using special cameras. You might not realize it, but overheating components, electrical faults, or mechanical wear often give off extra heat before you notice anything wrong. By catching these early signs, you can avoid breakdowns, fires, or costly downtime.

Think of it this way—you wouldn’t wait for your car engine to fail before checking it, right? Thermography lets you check your systems in the same way, before things spiral out of control.

Why It’s Important for Industries and Workplaces

⚙ Prevent Equipment Failures

Machines working under high pressure, loose wiring, or worn-out bearings—these things build up heat before they cause problems. Thermography helps you catch them early.

🔥 Safety First

Electrical faults or overheated components are fire hazards. Thermography helps you stay ahead of danger and keep your employees safe.

💸 Save Money

By spotting issues before they cause downtime or require expensive repairs, you save big in the long run. It’s prevention rather than reaction.

📋 Compliance and Maintenance

Regular thermography scans help you stay on top of maintenance schedules and meet safety regulations without scrambling at the last minute.

Where We See the Difference

We’ve been on sites where people thought everything was fine—until an infrared scan showed otherwise. One manufacturing unit had a motor overheating silently. They were just about to schedule maintenance next month when our scan helped them fix it immediately. Another office had faulty wiring behind walls—something no one would’ve caught without thermography.

These small fixes helped avoid major shutdowns, and the employees could rest easy knowing their workplace wasn’t waiting to blow up.

How Dr.SAFETY Helps You Use Thermography Right

✅ On-Site Inspections with Experts

We don’t just scan and hand over pictures. Our team walks you through what the images mean, what’s urgent, and what can wait.

✅ Tailored Reporting

Every facility is different. We provide reports that make sense for your operations, helping you plan maintenance without panic or confusion.

✅ Training Your Team

It’s not just about one-time scans. We help your maintenance staff understand how to monitor heat patterns and react proactively.

✅ Helping You Stay Prepared

Safety isn’t a one-time task—it’s a culture. We support you with periodic scans, updates, and advice to make thermography part of your routine safety checks.

Why You Need This

Nobody wants to deal with emergencies when there’s already enough going on. Thermography isn’t about fancy technology—it’s about peace of mind. It’s about knowing that your systems are being checked regularly, that small issues don’t turn into disasters, and that your employees are working in a safer environment.

With Dr.SAFETY, you get a partner who understands your challenges, speaks in plain language, and walks you through every step without unnecessary complexity.